PASSAIC VALLEY SEWERAGE COMMISSION -

Wallington Pump Station Improvements - Rehabilitation and Upgrades

LOCATION: PASSAIC, NJ

CLIENT: PASSAIC VALLEY SEWERAGE COMMISSION

MARKET SECTOR: PUBLIC

THE OPPORTUNITY

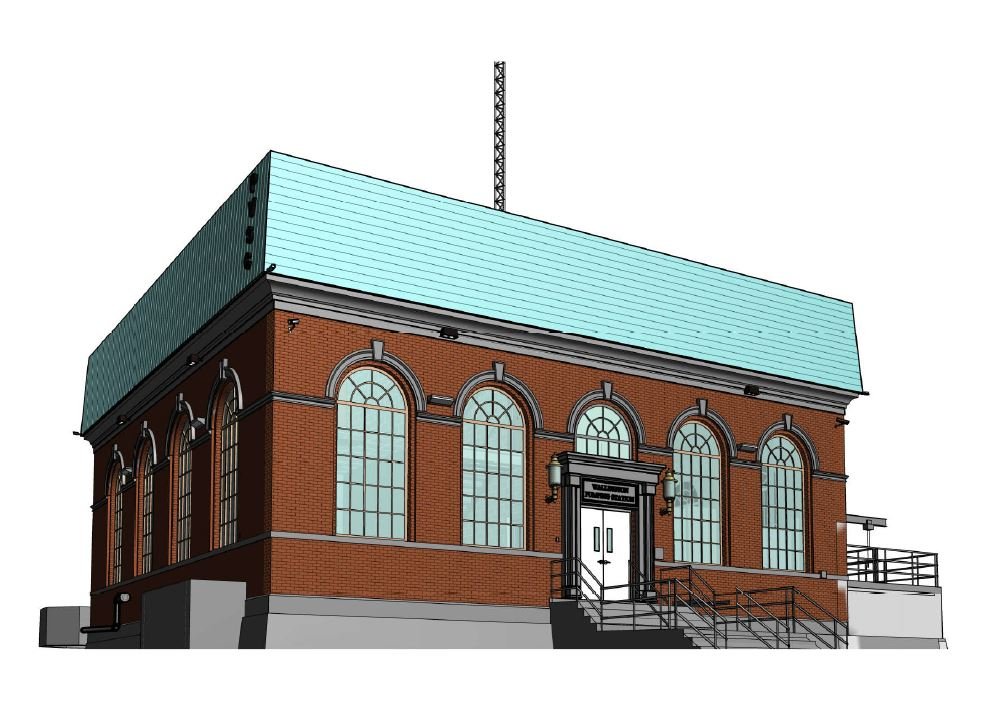

The PVSC intended to modernize their Wallington Pumping Station while maintaining its historic structure. The original pump station was place in operation in 1924 with the most recent upgrades and improvements being completed in the 1980’s.

THE CHALLENGE

The project entailed replacing the shaft driven pumps; replacement of the load resister banks with VFD’s; replacing the electrical equipment; address screenings in the wet well; bringing the building into compliance with current codes; interior renovations; reconstructing the main entrance stairs: construction of an access ramp; replacing the exterior windows and doors; replacing the interior doors re-roofing the building; repairing and painting the stucco; repointing the brick and waterproofing the building.

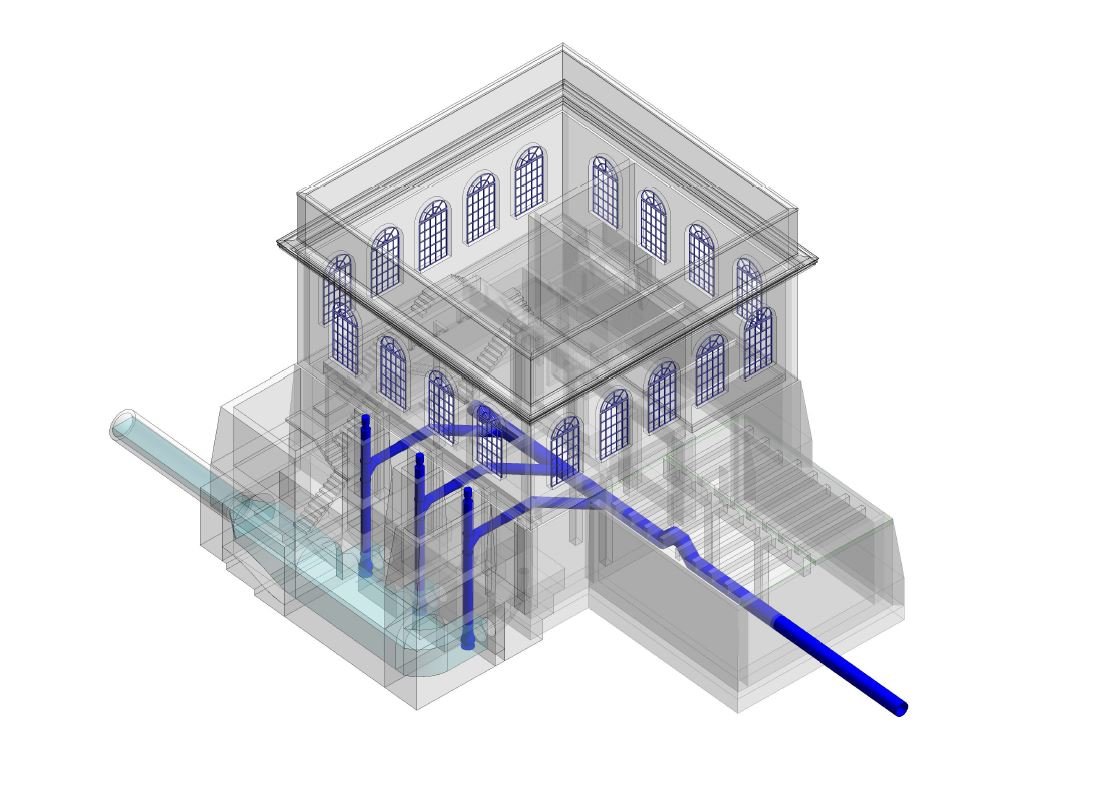

This overall investigation and subsequent design effort required significant evaluation of alternatives due to the driving force for the project, that of pump replacement. Other system upgrades due to building and site constraints, complicated hydraulic conditions, cultural resource considerations, code upgrades and flood mitigation also weighed heavily on the project. PS&S’s efforts have involved the review of numerous siting, equipment and facility upgrade alternatives that were complicated by the need to develop alternatives for PVSC’s consideration that would meet the requirements and intent of the design and be under the budget appropriated for the project. Complete topographic mapping was prepared at the Wallington Pump Station in support of the upgraded design. A 3D laser scan of both interior and exterior was performed to provide the raw data needed to prepare existing as- built drawings and a Revit model of the facility.

THE PS&S SOLUTION

PS&S worked closely with PVSC to develop a cost-effective program for the modernization and improvements to their Wallington Pumping Station. The Pump Station is designed to handle a “firm capacity” of 28 MGD and a peak design flow of 38 MGD. PS&S designed replacements for the aging shaft driven suction lift pumps using new long-coupled vertical centrifugal suction lift pumps. A new state of the art vacuum priming system will be installed operating independently on each pump and capable of overcoming the necessary 15 feet of suction lift. The load resister banks will be replaced with VFDs and new electrical switchgear.

The existing wide clear opening manual bar screens will be replaced with two (2) fine cutting comminutors with narrow clear opening vertical overflow bar racks. The comminutors will be installed in prefabricated 316 stainless steel flow channels with manual upstream slide gates. The use of prefabricated channels is expected to reduce the construction time for concrete channel work. A rock trap will be installed on the existing 54” reinforced concrete influent sewer, upstream of the Pump Station to remove potentially harmful materials that could damage downstream equipment. The rock trap will be supplemented with purge air, a vacuum connection and flushing water, all to assist in materials removal.